Analysis of building materials

At TESELA, we have been at the forefront of building materials development and analysis for over 25 years, so we understand the crucial importance of materials in any construction project. Our building materials laboratory is dedicated to ensuring the highest quality and performance in all the materials we develop, certify and validate. With a multidisciplinary team of chemists, engineers, art historians, doctors and geologists, we are dedicated to providing innovative and effective solutions for each of your projects.

Our commitment to quality and innovation

Our building materials laboratory focuses not only on the development of new products, but also on the certification and validation of existing materials, processes and products. All our materials are CE marked, reflecting our commitment to the highest standards of quality and safety.

Here, a multidisciplinary team of experts, including chemists, engineers, art historians, doctors and geologists, work tirelessly to develop materials that not only meet but exceed our customers’ expectations.

Services offered in our laboratory

Our laboratory is equipped to perform a wide range of analyses and tests, ensuring that each material meets the expectations of our customers and the relevant regulations.

Analysis and laboratory tests

The numerous tests we perform include:

- Characterization of materials: To thoroughly understand the properties and behavior of the materials used. This means that we not only evaluate the physical and chemical properties of materials, but also their behavior and durability under various conditions.

- Determination of Forms of Alteration: We identify and analyze the changes that may occur in materials due to environmental or use factors. This analysis helps to predict and mitigate possible deterioration, guaranteeing the longevity of the materials under real conditions of use.

- Determination of Physical-Mechanical Properties: We evaluate properties such as strength, elasticity and durability of materials. These tests are essential to understand how materials will respond under different loads and conditions, ensuring their suitability for safe and efficient construction.

- Artificial Aging Tests: We simulate the environmental conditions to which the materials will be exposed over time. This allows us to predict their long-term performance and durability, ensuring that materials maintain their integrity and functionality.

On-site testing

We carry out various on-site tests, such as:

- Cleaning Tests: We conduct detailed evaluations to determine the most effective and safest cleaning methods for different building materials. These tests are crucial to preserve the structural and aesthetic integrity of the materials.

- Selection of conservation treatments: We carefully choose consolidants and water repellents, along with protective treatments such as anti-graffiti solutions and special paints. These treatments are essential to prolong the life and maintain the appearance of the structures.

- Adhesion tests for mortars and paints: We evaluate the adhesion capacity of mortars and paints to different surfaces. These tests ensure the durability and effectiveness of coatings and finishes in buildings.

- Colorimetric studies: We carry out precise color analyzes to guarantee consistency and accuracy in the finishes. These studies are essential to maintain aesthetic uniformity and to meet specific design requirements.

- Definition of the project work system: We adapt and adjust the proposed treatments to the real needs of the project, considering both its technical feasibility and its economic impact. These studies ensure that the selected methods are practical and cost-efficient.

Control and monitoring of pathologies. Preventive conservation

- Management and implementation of quality controls.

- Study and design of restoration mortars.

- Monitoring of cracks and fissures.

- Monitoring of capillary dampness and evaluation of damp-proofing systems.

- Drawing up reports, intervention proposal reports, plans and quality control improvements.

- Selection of the most suitable products for any type of restoration during the construction phase.

Why choose our construction laboratory?

By choosing TESELA, you benefit from:

- A comprehensive approach for each project, from the characterization of materials to the determination of alteration forms and physical-mechanical properties.

- Technical assistance on site and active collaboration to guarantee the correct and effective application of materials and processes.

- On-site tests to determine the most appropriate intervention methodologies, including cleaning tests, selection of conservation treatments and colorimetric studies.

TESELA, your partner in materials innovation

At TESELA, we not only offer a construction materials laboratory; We offer a promise of innovation, quality and reliability. Whether for a new construction project or heritage restoration, we are here to provide material solutions that meet and exceed your expectations. Call us and find out how we can help you with your next project.

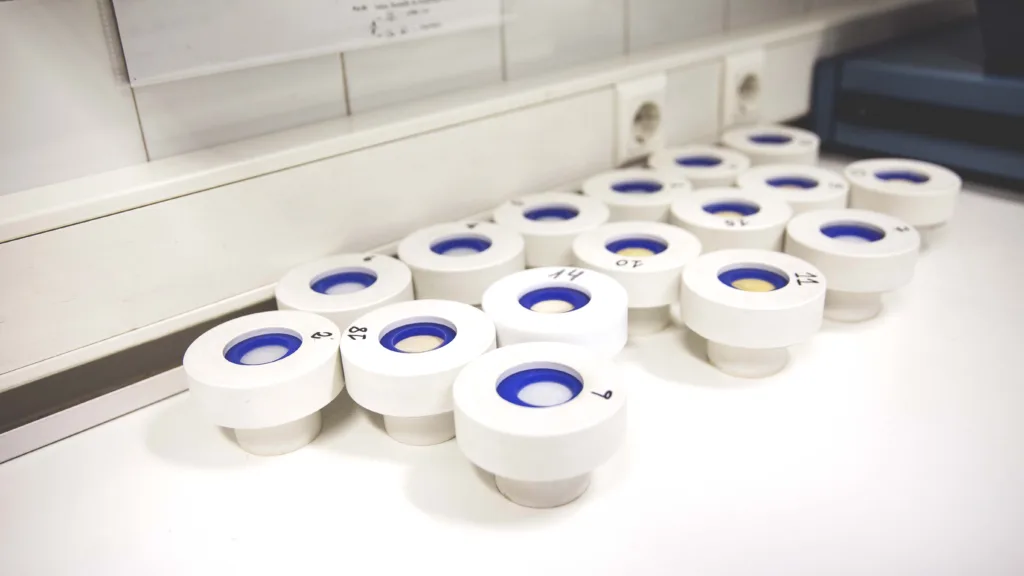

Some of our trials and analysis

- Friability coefficient in aggregates

- Determination of fines in aggregates

- Determination of the alkali-silica and alkali-silicate reaction. Chemical method

- Determination of alkali-carbonate reactivity in aggregates

- Fineness module in aggregates

- Alkali-silica potential reactivity. Accelerated method on mortar specimens

- Potential reactivity of aggregates with alkalis. Concrete prism method

- Determination of pH of water for mortar mixing and test specimens

- Clay lumps and other friable particles in aggregates

- Cleanliness coefficient

- Determination of water-soluble chlorides by Volhard’s Method

- Light pollutants

- Humus content in aggregates

- Water-soluble sulphate content.

- Total sulphur content by acid digestion

- Water-soluble materials

- Calcination loss

- Acid soluble sulphates.

- Chemical analysis of cements

- Magnesium sulphate test, except evaluation of complete aggregate particle sizes

- Freeze-thaw resistance

- Thermal shock resistance in aggregates

- Specific surface area of binders and additives

- Elemental analysis CHNS

- Determination of sieving grain-size curves

- Thermogravimetry (TG) (10ºC/min, air atmosphere)

- Chemical analysis of organic and inorganic compounds by means of Infrared Spectroscopy (FTIR).

- Flexotraction and compression resistances

- Determination of resistance to capillary absorption

- Chemical-mineralogical analysis

- Infrared thermography of facings/floors

- Determination of adhesion

- Adhesion after immersion in water

- Transverse deformation

- Determination of the bond strength of mortars

- Water tests (determination of the water vapour permeability coefficient)

- Water tests (determination of the coefficient of capillary absorption)

- Determination of water holding capacity

- Wetting capacity

- Volatile and non-volatile matter

- Ash content by direct calcination

- Determination of initial adhesion

- Hardening time

- Determination of air content in fresh mortar

- Open time of fresh mortar

- Run-off time (flow)

- Initial and final setting time (Vicat)

- Determination of workability. Run-off test of thixotropic mortars

- Determination of the workability of products to be applied via runoff

- Determination of workability. Concrete run-off test for repairs

- Determination of flexural and compressive strength of hardened mortar

- Chloride test on masonry mortars

- Rheological analysis of lime pastes

- Determination of workability. Application of repair mortars on substrates

- Determination of the carbonation depth in hardened concrete by the phenolphatelin method

- Determination of the bulk density of powdered mortar

- Determination of the bulk density of fresh mortar

- Determination of the bulk density of hardened mortar

- Determination of the consistency of fresh mortar by means of a shaking table

- Workability time

- Determination of compressive strength (including shearing and specimen preparation)

- Determination of physical characteristics of hardened mortar (including mortar preparation, determination of density, moisture content, shrinkage value, flexural and compressive strength).

- Digital image analysis

- Microstructural, textural, and chemical characterization by scanning electron microscopy

- Determination of the dimensional variation curve of the mortar (from time zero) for 48 hours.

- Compatibility of rendering mortars with masonry substrates

- Determination of the carbon dioxide permeability

- Resistance to carbonation

- Chemical analysis of organic and inorganic compounds by means of Infrared Spectroscopy (FTIR).

- Analysis of the attack of xylophagous insects on wood.

- Analysis of microbiological attacks.

- Study of the microbiota present in a sample of stone material to determine the presence of carbonatogenic bacteria to guarantee the effectiveness of the bioconsolidation treatment.

- Analysis of the causes of biodeterioration.

- Porosity and permeability to gases and vapours of organic supports.

- colourimetry

- UV spectrophotometry

- Electron microscopy (SEM)

- Fourier transform infrared spectrophotometry by attenuated total reflectance (FTIR-ATR).

- UV lamp examination.

- Analysis by Raman spectroscopy.

- Mineralogical analysis by X-ray diffraction (XRD) (including sample preparation, identification of mineral phases and semi-quantitative analysis).

- Elemental chemical analysis by X-ray fluorescence (XRF).

- Study of the porous system by mercury injection porosimetry (MIP).

- Accelerated aging tests (freeze-thaw cycles).

- Petrographic study (including thin film preparation, study by polarised optical microscopy and microphotographs).

- Durability test in climatic chamber.

- Water tests (determination of the coefficient of capillary absorption, water vapour permeability, absorption and drying at atmospheric pressure).