EUROPEAN Project. CALSILAM

Additive manufacturing of calcium silicate hydrate structures for acoustic and thermal insulation components.

The project aims to expand the potential of materials used in the construction sector as acoustic and thermal insulators by using an additive manufacturing process through 3D printing.

About CALSILAM

Current wall construction methods are based on a multi-layer system, where different materials are stacked (bonded or not) to achieve a specific requirement in terms of structure, sound insulation, thermal bridging, strength, etc.

The CALSILAM project seeks to solve this problem by using an innovative material developed that will have thermal and acoustic insulation properties (all in one). In this sense, this material will enable industry and the construction sector to reduce the traditional multi-layer wall system to a single layer. At the same time, the project introduces an innovative 3D printing concept to create large-format parts with this type of material. This will speed up the construction process and reduce the time needed to build walls, partitions, and structures.

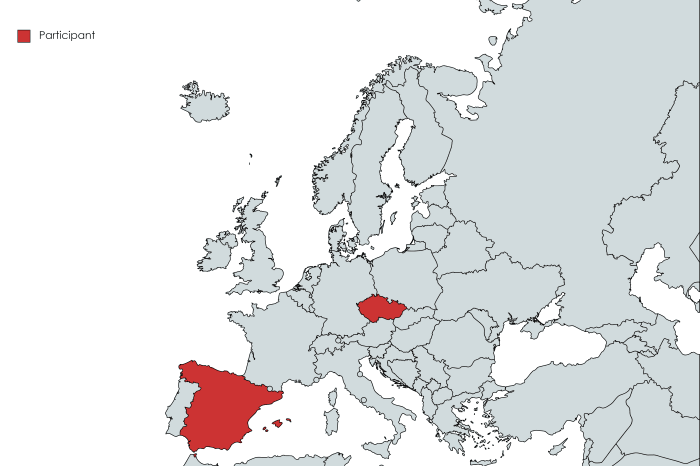

- 2 Participating countries

- 2 European regions involved

- Andalucía (ES61)

- Struhařov (CZ020)

- Galicia (ES11)

- TESELA, Materiales Innovación y Patrimonio S.L.: Expert partner in the development of advanced and sustainable construction materials in special mortars.

- PRINT4D SRL. Expert partner in 3D concrete printing technology systems.

- CETIM. A private, non-profit technology centre specializing in sustainable building materials.

CALSILAM Project Work Packages

Definition of the state of the art of the materials to be used as well as the technical requirements of the solution to be developed. Within this work package, the feasibility and time planning of the project is also included, as well as the internal coordination of material resources to ensure the success of the project.

Definition of the state of the art of the materials to be used as well as the technical requirements of the solution to be developed. This work package includes the study and investigation of cementitious materials, silicate-based materials, hydrated calcium silicate materials (CSH-based materials) and binders. Acquisition of materials and characterisation of calcium silicate raw materials and binders.

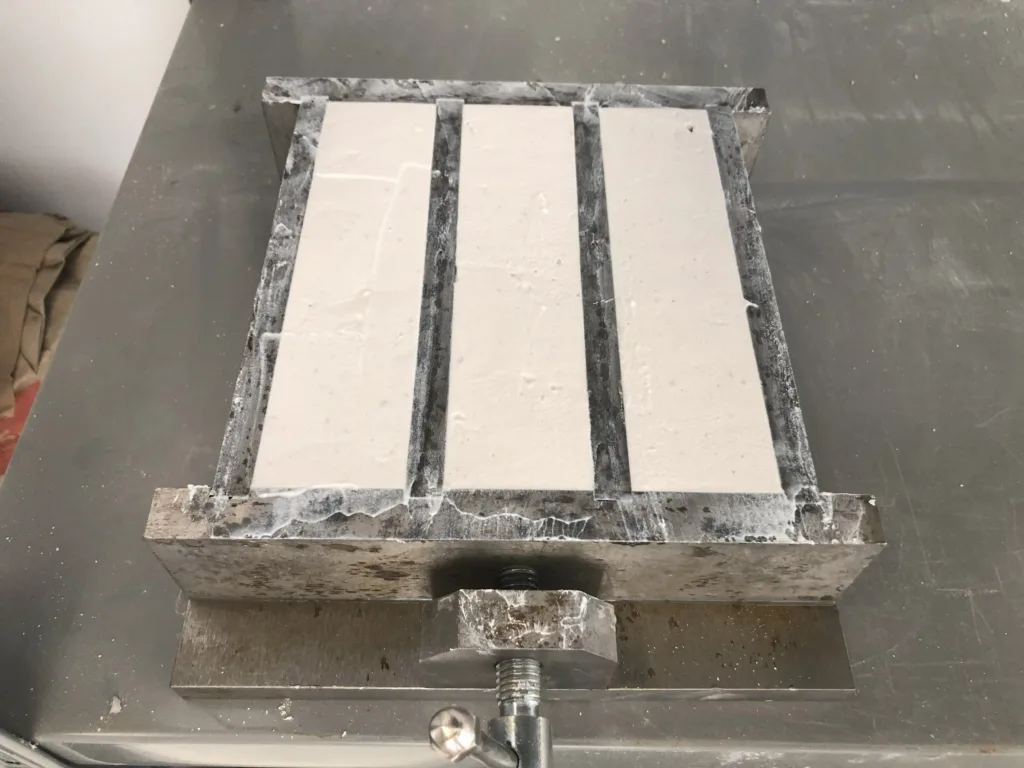

The aim of the third task is to evaluate and test different formulations of cementitious materials, silicate-based materials, CSH-based materials and mixed materials with different binders.

During this work package, the scaling of the 3D printing process, testing of the resulting parts, validation of the printing process and of the products obtained will be carried out. Once completed, the results of the project will be valorized, providing technical, environmental, and functional value for the construction sector.

Finally, during the final work package, the results obtained throughout the project will be disseminated and exploited.